After the pickguard was on the guitar, I reglued the neck to the body. Pretty straightforward. I use hot hide glue - just a bit on the sides of the dovetail and also on the mating surfaces of the fingerboard extension.

After the pickguard was on the guitar, I reglued the neck to the body. Pretty straightforward. I use hot hide glue - just a bit on the sides of the dovetail and also on the mating surfaces of the fingerboard extension.Here it is clamped up in the wonderful guitar vise while the glue dries.

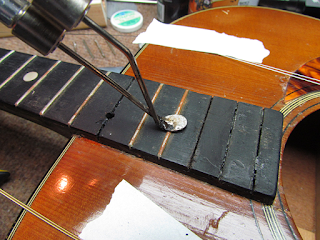

I needed to remove the frets prior to the heat straightening. Usually I use a soldering iron, but for some reason, these frets wouldn't budge. So I needed more heat and used a soldering gun.

The frets were really hammered in - I got way more chips pulling them out than usual. And part of the fingerboard pulled up to boot and had to be reglued.

Here are the frets in order as they were on the guitar. Note how the lower frets have that infamous green gunk on them, while the higher frets are much cleaner.

Now I'm going to straighten the neck with heat.

First I cleaned the filthy fingerboard with Simple Green. I'll use some good fingerboard cleaner later, but I wanted to get the worst grime off now.

And grimy it is.

I wanted to string the guitar back up and get an idea of how bad the upbow was.

Since the neck has been reset, the strings would lie flat on the fingerboard if I left the old saddle (see it on the left) in the bridge.

So I stuck a taller saddle from my parts bin in temporarily. The action won't matter; I just need to be able to have string tension on the neck.

You should be able to see the upbow in this picture.

Note how bowed upward the neck is at the nut (left) end. It should be straight, yet there is a significant bow upward from about the fifth fret down to the nut.

I'll get the neck straight with heat, then use compression fretting to (hopefully) keep it straight.

I'm using a fingerboard heating blanket from LMI. I'll heat the board up, then remove the blanket and use clamps to hold it straight.

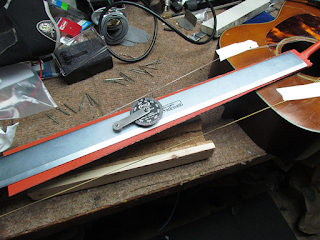

I'll be using a long straightedge at the 'bottom' under the clamps. The straightedge should help force the neck straight.

I put the straightedge on top of the heat blanket with a surface thermometer on it. Per Dan Erlewine's fret book, I'm aiming for a temperature of 225° F (about 107° C).

LMI sells a auto thermostat unit for the heat blankets. They have all sorts of warnings on their site about how fast the blankets heat up and that their warranty on blankets is not valid unless you use their thermostat.

I just ran the thing on my variac turned to 110 volts and watched it closely and it heated up fine. If I was heating guitar sides with it, I think the thermostat would be necessary. But for a small job like this - not so much.

At 225, I shut the blanket off.

Then (using gloves), I removed the straightedge and the blanket.

Then I put the straightedge back on and used my fret/fingerboard levelers on top and clamped it all together.

Here's the whole straightedge-leveling-blocks sandwich clamped down.

You could use one long leveling block piece if you have one. I don't, so I just used 2.

Here it is from the other side. You can see the aluminum level and my corian level blocks.

Also note the neck caul on the underside.

After it was clamped up, I let it cool.

I did the whole process a couple of times to make sure the neck was straight.

And...it is!

The neck is now straight up to the falloff of the fingerboard extension on the body.

The neck will not stay this way for too long. It will eventually return to the bow it had before. But it will be straight long enough for me to put new frets in which will have a tang a thousandth or so wider than the slot.

That will 'compress' the neck into a slight backbow which will then become straight under string tension.

That's the theory, anyway.

All posts in the 1931 Martin 0-18T Restoration Project:

- 1931 Martin 0-18T Guitar Restoration and Repair, Pt. 1

- Neck Removal on 1931 Martin 0-18T Guitar: Restoration and Repair, Pt. 2

- Trimming the Neck Heel for Reset: 1931 Martin 0-18T Restoration and Repair, Pt. 3

- Shimming Guitar Neck Dovetail and Finish Chip Repair: 1931 Martin 0-18T Restoration and Repair, Pt. 4

- Caul for Heat-straightening Guitar Neck: 1931 Martin 0-18T Restoration and Repair, Pt. 5

- Reparing Acoustic Body Cracks: 1931 Martin 0-18T Restoration and Repair, Pt. 6

- Making a Tortoloid Pickguard: 1931 Martin 0-18T Restoration and Repair, Pt. 7

- Heat Straightening Bowed Guitar Neck: 1931 Martin 0-18T Restoration and Repair, Pt. 8 - This page.

- Fret Marker Installation and Filling Fingerboard Chips: 1931 Martin 0-18T Restoration and Repair, Pt. 9

- Compression Fretting to Correct Upbow: 1931 Martin 0-18T Restoration and Repair, Pt. 10

- Completed 1931 Martin 0-18T: Restoration and Repair, Pt. 11

0 comments:

Post a Comment