My workspace, The Dungeon, has way too much clutter, clutter that is even all over the floor. I can hardly more without tripping over something. I can imagine ruining a fragile guitar top by tripping over, say, a machine press or an amplifier lying on the floor. And I can't really build instruments on my current benches - they are against the walls and can only be accessed from the front.

With that in mind, I set about building a simple but functional workbench that will serve as an assembly table which I can access from all sides. And it will have some room for storage on the bottom.

I studied a lot on the interwebs about DIY workbenches, and read some books to get ideas. It struck me that workbenches are personal - in the sense that if you're making one, it should serve your needs. It's fine to make one from a plan, but there may be shortcomings or features you don't need. I saw many incredible woodworking benches, many variations on the Roubo bench, etc. But I'm not building cabinets. I'm building instruments. I just need a solid table I can put guitars together on. So what I came up with is quite basic.

Did a lot of thinking, made some drawings, made some revisions and then went at it.

In this shot you can see what I mean about the jumble. Guitars, parts, cases, just stuff everywhere.

I procured some 2x6s, 2x4s and had some nice 3/4 inch birch ply cut to size at the dreaded Despot.

Here's some of the birch ply. It will become a shelf and the tabletop.

Cut the 2x6s to length with my cheap semi-trusty Ryobi miter saw. Works great for straight cuts, but not so good with actual miters.

I tried making 45 degree cuts one time only to find the saw scale is off by a degree or so. Wound up aligning it by hand to cut the miter, can't rely on the scale on the saw.

I just used screws - #10 and #12 - for the assembly. In a nod to good construction practice, you can see I used a square.

The basic frame is just 2x4s. I did try to get reasonably straight ones at the Despot, and these are supposedly "premium."

The bottom frame along with the legs before I attached the legs.

Did I say this was going to be simple?

Note the legs are exactly the same length! My saw got something right for once.

Attaching the legs. Just clamped the 2x6s to the 2x4s, then screwed them together. It seemed like a good idea to vary the fasteners on a slant. Who knows if it really matters in practice, but it looks neat.

I love countersunk holes. I drilled a pilot hole, then countersunk it, and then drove the screws in. I have 2 drills, so I didn't have to switch out bits a lot, which made this go faster.

Now we're getting somewhere.

This is the basic frame. When I said simple, I meant it!

Even though my legs are even, I found that different spots in my floor are not level. Probably not surprising. In one spot, the frame was solid, but 2 inches from that, it wobbled. I'll just have to put a shim under one of the legs when it's done.

Some more 2x4s go in as bracing and to support the bottom shelf.

Note that I have them sitting about 3/4 of an inch below the top surface of the side braces - the shelf will then sit perfectly flush with the sides this way.

I tacked in a couple of the braces, checked the height with the shelf, then assembled all of the braces. I wanted to make sure the shelf would sit level and not protrude above the sides.

Here's the shelf fitted in place. You can see how it sits flush. I didn't bother using any fasteners to hold it in place. It fits pretty snugly, so I figured, "why bother?" If it starts to warp, I'll screw it down to the braces.

Then I put in the top braces. They sit flush with the sides, since the top will overhang the whole thing.

Now for the top.

I had the Despots cut my top (and shelf) to size from two 3/4 inch birch ply 4/8 sheets. The top is 60 x 30, if you're curious. I am staying away from showing my plans or exact measurements, mainly because you should figure out what you need and size it to suit.

Then I used the excess from those cut sheets to make up a second layer to laminate to the top. Originally I thought I'd have them cut 2 full sized pieces, and glue them together, but I realized I'd have enough from the leftovers to make a bottom layer pieced together.

In the picture above, the full top is the bottom piece, and the top is one of the cutoffs. I just marked it and cut it (with a jigsaw!).

Spread glue on the bottom of the full-size top piece.

Then clamp down the pieces that will be the bottom on the final tabletop.

You can see I used almost every clamp I had around the edges, and used my drill press bottom (sigh...not done yet, but SOON) and my URM-25D (yet another project in the wings) to weigh down the center.

Note the seam under the URM-25; that's the join from the 2 pieces of ply I used. The whole thing will be flipped over when it's dry and the top will be one clean sheet.

My cut with the jigsaw wasn't super accurate, so I have a couple of spots I need to even up. This is probably the worst area.

I ran around the edges with my trusty Ridgid trim router to even the top's edge.

I took this shot to show the cloud of laminate dust that went everywhere!

I wanted to avoid having any screw holes on the top. In doing some research on the Interwebs, I read about using dowels to locate the top and keep it in place.

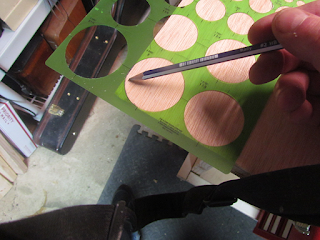

Drilled some 3/4 inch holes in one corner of each leg with a forstner bit. I love those things! And I have

Procured some 3/4 inch oak dowel stock and cut it into four 3 inch lengths. I could have used more generic dowels, but these are much stiffer so I splurged and spent $2 more for oak.

This is a test fit, it's not driven all the way in. The mark on the dowel is at 1/2 inch- the depth of the hole I'll make on the underside of the top.

Originally, I figured I'd glue the dowels in, but the fit was so tight I didn't bother.

With all of the dowels (pins?) in place and raised up a bit, I got the tabletop lined up exactly where I wanted it. (There's a bit of overhang on the ends and sides and I measured it to make it even).

Then I marked where each dowel lined up.

Now you see where this is going.

Drill a 1/2 inch deep hole in the tabletop and you're there.

This shows the two respective holes in the frame and the top, and the mating dowel.

Someone on Lumberjocks, I believe, mentioned chamfering the edges of the dowel to help it fit. Probably not necessary, but I hacked each dowel with a file to take that sharp corner off.

Glad nobody will see that, it looks awful.

Then line the top up, and whack it down on the dowels with a mallet.

The mounting works great!

The top is heavy enough to stay in place, and the dowels prevent it from shifting. And it can be easily lifted off if needed.

In a final nod to semi-craftsmanship, I traced a 2 inch diameter semicircle on each corner of the top.

Cut the corner off with a hacksaw, then used my fabulous Japanese rasp to round it off.

You can see the top is already chipping a bit, and that ply doesn't look great from the side, so I'm going to put some edge banding on it soon.

Here's the final table. Simple but effective.

I already am storing stuff on the bottom! That little tool chest has been on the floor for years. Now it has a home.

Another angle. Perfect place for that gallon of wood glue.

I eventually want to build a cabinet with drawers or shelves to hold more stuff, but this was a good start.

From the other end.

You see how I can get to anything on the top from any side. That was a major plus - my other workbenches are against walls and only accessible from the front.

In addition to a cabinet on the bottom, I'm going to take a shot at putting a thin-ish maple top on it too. The ply is already getting dented just from installing it, so I want a layer of solid hardwood. Stay tuned for that.

0 comments:

Post a Comment