As a woodworking tool, go-bar decks date far back. Modern luthiers have put them into use to clamp down top and back braces on instruments. One could also use clamps, but they bulkier, harder to adjust, not to mention you'd need a lot of clamps.

LMI and Stew-Mac sell nice go-bar decks, but I figured I could make my own and save some money to put toward tonewood.

I procured a couple of 24 x 48 x 3/4 inch pieces of MDF from the Despot. I originally wanted to use 3/4 inch plywood, but there were no sheets of that size at my local Despot that day, so MDF it was. Usually I

I cut each piece in half in order to wind up with four 24 x 24 pieces. Some of my luthier buddies at the ASIA symposium this summer suggested making the decks as thick as possible to make the assembly study and to help the top deck resist bending when putting the clamp bars in place.

Then I set about laminating two of the sheets together. Here I am spreading Titebond onto the surface of one of the pieces.

I used a cheap disposable 3 inch brush to spread the glue.

And then clamped it down using clamps around the edges and my trusty AN/URM-25D signal generator to hold down the center.

The generator is still in my long restoration queue, but it makes a darn good weight even when unrestored.

I had a lot of glue squeeze-out. I spent about 10 minutes going around the edges with a damp rag cleaning it up. And I still found squeeze-out after it was all dried.

After this deck dried, I glued the remaining 2 sheets together the same way.

The plan is to put four threaded rods in the corners of the bottom deck to hold the top deck up, and allow the top deck to be adjusted up and down for height.

I put a radius dish on the soon-to-become-the-bottom deck to determine where the rods could be located on the corner.

The dish is made of Extira MDF. I have a 15 foot radius (for backs) and a 30 foot radius (for tops). I'll talk more about the dishes in a bit.

I decided where to drill the pilot holes on each corner. In a fit of accuracy, I used a ruler and roofing square to mark them at the same place in from the corner at a location 45 degrees from the side.

It's important to locate the holes at the same places on the decks, since their location will enable the top and bottom decks to be square with each other.

I had read on the Interwebs that the cut ends of MDF should be sealed to prevent moisture from getting in and warping the boards.

Here I am using spray shellac to paint the edges. Shellac in a can! What a great thing.

Now we drill a pilot hole in the corners we marked earlier.

I think this was a 1/8 inch bit, it's not that critical. Just something to guide a bigger bit.

Then it's over to the King-Seeley drill press with a 9/16 bit to make larger holes.

Those decks are heavy and without a proper table on the press (another upcoming project...), I had a heck of a time balancing the deck(s) and operating the press at the same time.

I'm putting threaded tee inserts into the bottom deck. The rods will thread (duh) into these to hold the top deck up.

The rods I'm using are 1/2 inch x 36 inches, 11 threads per inch I think. So the inserts are the same thread.

I get all of this stuff from McMaster-Carr, probably the world's greatest resource for hardware. The downside is on fasteners and the like, you can't buy, say, just 4 of something. You have to get a bag of 25 or 50.

Their website is incredibly well organized and easy to use, especially given they have tens of thousands of items. And there are detailed drawings, diagrams and information for all of it. Simply incredible. I love them!

The spikes on the inserts will probably hold them in place just fine, but I put some JB Weld in the holes as well.

Then just drive the inserts into the holes with a mallet.

The top deck needs to be able to slide up and down on the rods. I'm using 3/4 inch copper pipe left over from plumbing repair, in the holes. I polished the pipe up to remove corrosion as you would if soldering it. I'm going to epoxy it into the holes.

And here I am cutting the pipe to length. This is one of my favorite tasks and tools. I love using a pipe cutter to cut pipe. These cutters (even my cheap one) are such cool tools to use. I suppose if I had to do this for a living, I'd get sick of it. But it's fun on those rare times when I do it.

Mix up some more JB Weld and spread it on the pipe pieces.

Note the rods in the background. Oh, I have plans for you boys!

Then place the pipe in the holes and drive it in. I didn't want to make the fit too loose, it's nice and tight and with the epoxy, the pipes won't go anywhere anytime soon.

The rods I have are 36 in. long. I am planning on using 24 inch rods, so the space between the bottom and top decks will probably be around 22 or so inches. Which means I can cut the rods to a shorter length.

I measured the thickness of the top deck, allowed for a bit extra, and came up with 28 inches for the rods. This really isn't a project where we need high precision; I just want the rods to be trimmed down a bit.

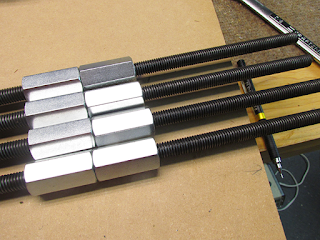

Here are the rods lined up ready to be cut.

Note that I put a couple of nuts on them before cutting it, we'll see why momentarily. The nuts are threaded on a couple inches below the cut marks I made with a Sharpie.

It's easy to make the rods shorter. You could use a hacksaw, or do as I did and use a grinder of some sort. I used a Dremel with a reinforced cutting wheel. Marked the rods with a Sharpie so the marks would be easy to see during the cutting.

I like making sparks.

You might be thinking: "How will the threads work after cutting?" Experienced machinists or metal workers know it's easy to clean up the cut threads. I learned how to do it in High School metal shop class.

We used files then, but since I have a nice Baldor grinder, I'll put it to work.

Grind the end of the cut rod flat.

Then undo the top bolt over the end of the rod. This will cut a new thread at the end.

Obviously my bolts are long due to the way I'm going to use them, but regular shorter bolts will work just as well.

Hard to photograph, but you'll see we still have some burrs on the rod. The burrs were drawn upward by the bolt - making it easier to remove them.

Grind the burrs off by holding the rod on an angle on the grinding wheel - it will only take a second or two to knock them off.

If you still have burrs, use a file to get them all off. As I mentioned earlier, you can use a file for the whole operation if you don't have a grinder. Just takes a bit longer.

Here's our finished rod. Looks good. You can run the second bolt up and down over the cut to ensure it works smoothly.

It's easy to do this on a coarse thread like this, but the process works the same way for finer threads.

Assembling the deck is easy.

The rods thread into the inserts on the bottom deck plate.

Put one nut on each rod, and run the top deck over the rods. The copper pipe insert lets the deck slide up and down easily over the rod as needed.

Then put the top nut on to lock it down.

The height of the top deck can be easily adjusted with a wrench. I used longer bolts because I figured they'd be easier to adjust.

You could also use knobs - I considered that but figured since the bolts were cheaper, I'd try them first. If they turn out to be too much of a hassle, I'll spring for some knobs.

You can see some glue squeeze out I missed too - shucks. Not a big deal.

Here's how the go-bar deck works in practice. Very simple and ingenious.

Your radius dish goes on the bottom. Then your instrument's top or back goes on the dish.

Glue the braces on where you need them, and use rods placed between the top deck and the brace to clamp down. Adjust the height of the deck to put pressure on as needed.

I stuck some thin wood rods on there to demonstrate for this picture. In practice I'm going to use 24" fiberglass kite rods since they will flex easily and should work under a fair amount of pressure.

The whole deck is heavy and pretty large. Fortunately it's not difficult to break down for storage.

0 comments:

Post a Comment