Seems this is not uncommon on these machines, and the fault is usually failed electrolytic capacitors! Can you believe it? I have years of experience in replacing capacitors in radios and amps, so I was encouraged that the problem was something I could fix.

I took it apart to test it and recap it if needed.

Here's the patient. I bought this machine used, and upgraded it to 32GB of RAM and put an Asus Xonar sound card in it.

We take the cover off to get to the innards.

All of the various bits come out easily. There's actually a diagram on the chassis that illustrates how the pieces come out.

This is the Western Digital Caviar Blue hard drive. Squeeze the two blue tabs and it comes out. Then you can remove the ribbon cable that connects to it.

The drive needs to come out so you can get to the main connector from the power supply to the motherboard.

So, Caviar Blue? I had the greatest caviar ever in Stockholm about 2003 when I was on an automotive press junket covering the then-new SAAB 9-3 Sports Sedan. But it was not blue.

Same general approach for the DVD drive. Push a tab, remove the drive and its connectors. We need to remove this drive to get to another connector underneath.

Under the DVD drive is another power connector from the power supply to the motherboard. There's a clip on the side that releases to remove the connector.

And this is the main connector under the hard drive I mentioned earlier. Like the white connector above, it has a clip that needs to be released in order to remove it.

Three screws on the outside of the chassis hold the power supply in place.

You can see there is a power supply test button on the right to the IEC AC connector. If you press it with all of the peripherals disconnected (the drives), the green light alongside it will turn green, and the fan will spin, meaning the power supply is ok. Mine failed this test.

The power supply can now be removed from the computer.

The aluminum box holding the power supply is held together with a bunch of Phillips head screws. Most of them will take a bit of torque to turn. They are also cheap and the heads will be damaged easily.

Guess how I discovered that?

If I cut this anti-tampering label, my guarantee will void.

Bummer.

The label cleverly covers one of the screws we need to remove.

Long story short.

One of the stupid screws was so tight and frozen in place that I couldn't remove it, and my trusty Wima screwdriver began to strip the head! Even soaking with PB Blaster didn't help.

So I wound up drilling the screw out.

And then removed it with a screw extractor. I have a couple of sets of extractors (aka easy-outs) around and they come in handy.

Stupid cheap screw. How much torque do you need on this thing? Sheesh.

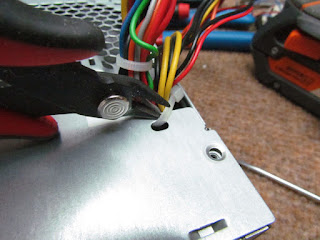

The various cables are secured to the case with a wire tie, which we need to snip off.

The top of the case comes off, exposing the power supply board.

There are four screws holding the board in place.

Sure enough, there are a number of electrolytic capacitors with bulging tops, a clear sign they have failed.

I generally don't see this in old radios or other gear - in those applications, the caps have just become electronically 'leaky' over time. Those old caps almost always look ok, but they are bad. You can't generally tell they are bad by just looking at them.

This is one of the rarer instances where the caps are visibly bad.

The yellow arrow points to the hole in the PCB for one of the mounting screws (screw removed). I took this shot to show that the test switch (hanging loose above the hole) needs to be removed to access this specific screw.

With the screws removed, you can lift the power supply assembly out of the chassis.

The AC line connector (white) needs to be unplugged from the board to get the whole assembly free to work on.

Here's the power supply removed from the chassis/cabinet/case.

Now we can get at those caps and replace them.

I have a saying: it's not a project unless there's an injury. Not as extreme as Sven's though.

Fortunately he's healed and back doing beautiful work.

Removing the caps on a computer is no different than any other piece of equipment. I prefer solder wick over solder suckers. The cheap suckers (ha ha) are useless. Wick gives you a much cleaner hole or connection to work with.

One thing I found with this board is that the solder Dell uses doesn't like to come off easily. I heated it as usual, but no dice. I suppose it's lead-free solder. I'm all for it in theory, but my few experiences with it haven't been that great. Mainly, as on this board, it's the very Dickens to desolder.

But I have had success working with it: I melted a bit of new solder onto each joint, and then the joints came clean easily. Just something to be aware of.

Keep your iron's tip super clean too - the pic above is NOT a good example. I'm really good about keeping it shiny, but that's not evident there!

One thing I really liked about this pcb is the way the polarity for the caps is marked - the shaded black area is negative. Makes it easy to identify.

On this specific spot, the two caps in the back were buried under white silicone. So much silicone, in fact, that I didn't even see them when I first had the power supply out and was making a list of caps to buy from Mouser. Fortunately I had those two values on hand.

I try to use the best quality caps I can in stuff I work on, which means Nichicon, Panasonic, or ELNA.

This is the biggest cap on the board - rated at 450 volts. You can see the original 'Elite' brand cap versus the new Nichicon I replaced it with. Ever heard of Elite? Me neither.

Unfortunately, a lot of modern gear uses cheap components such as this cap. This is why there is a high failure rate- this computer was built in 2009, yet the power supply caps have failed. I generally see a 20 to 25 year life in gear I work on - which had quality components to begin with.

Places such as Mouser only sell good stuff. Don't be tempted to try and 'save' money by using no-name stuff in gear you repair or build. Generally, the price difference is only a few cents and the peace of mind and performance difference far outweighs the perceived cost savings.

Here's the power supply, freshly rebuilt with new electrolytics. Got rid of a bunch of that awful silicone too.

I believe there were a dozen caps I replaced.

Why would I do this versus just buying a replacement supply, you ask?

First, cost. I put less than $10 worth of parts into this, as opposed to $55 for a new supply. I could recap 5 of these for the cost of just 1 new one.

Second, a new supply would use those poor quality parts the original did!

Third, other than the capacitors, everything else on the board works fine. Why trash it?

Moment of truth.

Reconnect that AC plug to the power supply board, and connect the AC cable to the IEC connector.

Press the test button and the fan spins! Whoo hoo! We have a good power supply!

Now we just reassemble the whole power supply and put it back into the PC.

Here's the power supply back in, along with all of the drives reconnected.

The real test, of course is to connect it back up in the studio and boot it up.

'Studio' in this case is a small corner of the bedroom.

It works!

Now let's make some noise.

Think of the thousands and thousands of these machines that have junked over the years for a few cents worth of parts. Machines that still had plenty of usable life in them. Most people would have stopped troubleshooting at the point it wouldn't turn on, thrown their hands up and called it a piece of junk and moved on. Not you. Well done.

ReplyDeleteHey There. I found your blog using msn. This is a very well written article. I’ll be sure to bookmark it and come back to read more of your useful info. Thanks for the post. I’ll definitely return. 54y8876

ReplyDeleteHi i wonder about one of ceramic capacitor blown idont know what is the value of it

ReplyDeleteAre you sure it's a ceramic cap? At any rate, there should be markings on the cap indicating the value - they may be a code like "103," "472" etc. Find the code and decipher the value.

DeleteThe screws are not Philips but Pozi Drive us should use a Pozi driver not a philips driver

ReplyDeleteThanks. I shall add a Pozi drive set to my arsenal. I don't take computers apart much!

Deletegood to know. Thanks

DeleteHow do we know/test that capacitor is broken? Assuming use the avometer.

ReplyDeleteThe only way to really test is with a capacitor checker, not just a volt/ammeter (aka Avometer, VTVM, DMM, etc.)

DeleteThe capacitors in those power supplies are cheap and tend to have a short life. In researching this issue, I learned the specific blinking of the pilot light on the PC generally meant power supply issues. And the number one point of failure in power supplies are filter capacitors. (Just as they are in radios and amplifiers, which I am very familiar with).

Capacitors are cheap, just cents (pence) so it's easy and inexpensive to replace them. And, not too surprisingly, the issue was resolved.

hello

ReplyDeletei have same this power supply

but 7pin ic burn i want that part number

only i know start with tny

please help me

wow thats so cool

ReplyDeleteHi there, i just read ur article. I have the same pc - dell optiplex 780, with a problem i think u can help me out with.

ReplyDelete2 yrs ago it stopped starting normally with power button. I googled and came up only with this way which is a painful repetition i did for 2 yrs.

To boot the pc, i have to unplug hdd and dvdd power plugs first, then press and hold the the supply test button at the back, then amber lights and fan starts n i let it for some 1 to2 min. Then turn of then hold power button for 7 blinks of number 3 , at the 7th blink the supply test button press starts my pc- sometimes it fails an start over again.

From ur article i understood the p supply is ok, so what would u think is z problem, n z solution 🙏 please help me out.

i fuckin got the sol'n so fuckn forget it bitches.

Delete